Production Technology

RAW MATERIAL

We have ample inventory of high-quality raw materials from around the world, including pipes, aluminum, seals, springs, shock absorber oil, and other components.

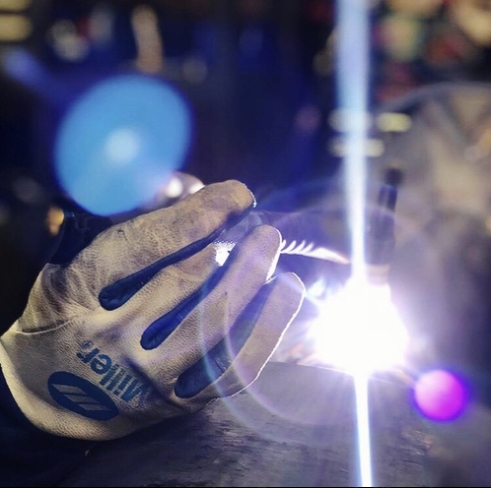

CNC MACHINING PRODUCTION PROCESS

In the production process of off road shocks components, advanced CNC machining technology is used to ensure high-precision tolerances between shock absorber components and surface quality control of products to meet the requirements of hydraulic fluid characteristics, improve the sealing performance of shock absorbers and the durability of components during use, and comprehensively enhance suspension performance.

PRODUCTION CHARACTERISTICS, MATERIALS, PERFORMANCE

+CNC machining technology, high precision machining, effective control of machining accuracy within the range of+-0.002

+CNC speed control cutting forming effectively improves product structural strength

+6061-T6 aviation aluminum shock absorber components

+7075-T6 aviation aluminum shock absorber connection structure components

+The smoothness of the shock absorber cylinder is 0.2-0.35RA, and the hardness of the shock absorber cylinder is 55HRC

+OE shock absorber oil pour point -45 ℃ flash point+185 ℃

+Competitive shock absorber oil pour point -25 ℃ flash point+263 ℃ (adjustable according to usage needs)

CNC MACHINING PRODUCTION PROCESS

In the production process of shock absorber components, advanced CNC machining technology is used to ensure high-precision tolerances between shock absorber components and surface quality control of products to meet the requirements of hydraulic fluid characteristics, improve the sealing performance of shock absorbers and the durability of components during use, and comprehensively enhance suspension performance.